Plant Design Systems (PDS) Training

Plant Design System (PDS) Training

Description

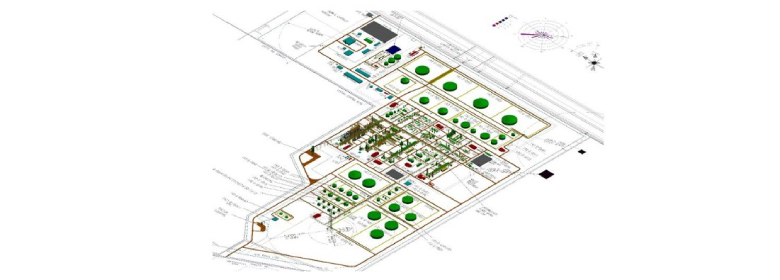

This class is for Piping Designers who will create piping models, and other users who will create related reference data. The class features an introduction to the graphics environment, equipment modeling, followed by routing techniques for piping modeling and generation of isometric drawings.

Major Topics: Overview of Common Graphics Environment – Defining a Working Set – SmartStep Commands and User Options – Interactive Interference Checking – Equipment Modelling – Piping Modelling 3D Routing System – General Routing Techniques – Hangers & Supports – Change Management – P&ID Integration – Isometric Drawing Generation – Structural work & Electrical / Instrument Cable Tray.

Eligibility

ALL Mechanical / Production Engineers Chemical / Petrochemical Engineers Civil Engineers Electrical Engineers Instrumentation / Electronics and Telecommunication Engineers ITI / Mechanical / Civil / Electrical Draftsman / B.Sc, Piping Engineers Piping Draftsman Engineers / Draftsman / Any Graduates.

Prerequisites

Key Points syllabus

- Equipment Modeling by Primitive method.

- Equipment Modeling by Standard method.

- Nozzle Manipulation.

- Equipment& Nozzle report extraction.

- Piping modeling by connect method

- Piping Modification.

- Consistency check.

- Clash check.

- Line report extraction.

- Piping Modeling by explicitly Method

- Instrument and special items

- Slopeling Modeling

- Structural of Different Types of Plat forms rectangular & circular

- Structural Modeling Stairs/Ladders

- Isometric Extraction.

- Error Resolving.

- Draft Extraction

- Draft Dimensioning Tagging Labeling

- Oil and &Gas, Petrochemical, Refinery, EPC

- Power Plant & Energy Sectors

- Refineries, Petro-chemical, Process Plants (Pharmacy, Paper, Tyre, Sugar),Process and Plant Design

- Pharmaceutical, Water Treatment, Building Services, Shipbuilding and Architectural

- Chemical, Power, Offshore, Food, Beverage, Brewing,

- What is the Plant Design System?

- What are the 2D modules?

- What are the 3D modules?

- Project Setup

- Project Organization

- Working in Three Dimensions

- SCOPE

- OUTLINE

- HANDLING OF PDS REFERENCE AND PROJECT DATA

- DETAIL OF PDS REFERENCE DATA

- DETAIL OF PDS PROJECT DATA

- DATA SERVER AND FOLDER STRUCTURE

- PURPOSE

- ITEMS TO BE MODELED IN PDS EQUIPMENT MODULE

- TYPES OF EQUIPMENT WITH THEIR

- CORRESPONDING PDS FORMS

- EQUIPMENT NOZZLES BY NOZZLE MANIPULATION

- MISCELLANEOUS EQUIPMENT

- PREPARATORY GUIDE AND INFORMATION PRIOR TO MODELING

- MODELING INPUT PROCEDURES

- UPDATE PROCEDURES FOR MODELED ITEMS

- S41 DATA HANDLING

- SLOPE VESSEL

- HANDLING AND REFERENCES

- PURPOSE

- BULK COMPONENTS

- PREPARATORY GUIDE AND INFORMATION

- MODELING INPUT PROCEDURES

- UPDATE PROCEDURES FOR MODELED ITEMS

- PDS ASSEMBLY

- JACKETED PIPING

- STEAM TRACING

- Weld Point

- Reference Document

- GENERAL

- OUTLINE

- STANDARDSUPPORT

- SPECIAL PIPE SUPPORT

- SPRING SUPPORT

- GENERAL NOTE FOR SUPPORT INPUT

- Welcome to PE-HVAC

- Main

- Utilities

- Reference Symbology

- Section Line Dimensioning

- Engineering Utilities

- Annotation/Schedules

- Integrated Commands

- Error Messages

- Edit / Review Functions

- Customizing PE-HVAC

- Level Schemes

- Eden Symbols

- Hierarchical Associated List (HAL)

- Files

- Glossary

- SCOPE

- COMMON TOPICS

- PDS DATA HANDLING

- MODEL REVIEW DATA

- REPORTING

- MTO

- ISO DWG

- PLAN DWG

- PDS STRESS ANALYSIS FOR CAESAR II

- INTERFACE

- Scope

- DesignReview Integrator

- DesignReview Defaults Setup

- DesignReview Administrator

- DesignReview Tag Environment

- DesignReview Model Transmittal

- Drawing Manager Overview

- Drawing Management

- Drawing Manager

- Graphics Environment

- Composing Drawings

- Copy Drawing View

- Revision Markers

- Update Annotation Labels

- Vector Hidden Line Manager

- Search Criteria for VHL

- Annotating Drawings

- Plot Manager

- Project Planner

- Project Setup

- Plot Setup Manager

- PURPOSE

- GENERAL

- REFERENCES

- SCOPE OF WORK

- ORGANIZATION

- 3D Model SET UP

- MODELING ITEMS

- CONTRACTOR’S CUSTOMIZATION

- ENHANCEMENTS

- ORGANIZATION FOR 3D MODEL

- IMPLEMENTATION

- QUALITY CONTROL

- PDS FAULT LOG

- PDS MODEL CREATION

- CLASH CHECK

- 3D MODEL REVIEW AND PROGRESS OF EACH

- REVIEW

- MATERIAL TAKE OFFS (MTO)

- EXECUTION FLOW

- DELIVERABLES EXTRACTED FROM 3D MODEL

- Piping Drawings

- Civil Design Drawings

- Electrical Design Drawings

- Instrument Design Drawings

- What is the Project Administrator?

- Process & Power PDS Overview

Certification

Candidate receive the course certificate after completing the Plant Design System (PDS) Training with Arka Solutions.

Courses

course schedule

Batch No

1

Full Time

30 Days

(240 hrs)

Part Time

Saturday & Sunday

(3 months)

Timing

9.00 AM -

7.00 PM

Training Type

Individual

Level

Beginner to Pro

Project

1

Useful Links

Class Room Training

Keep in Touch

Address

- : No.986, Angalamman Koil 3rd street, Kolathur Main Road, Mambakkam Chennai-600127

- : +91-044-27479336

- : +91 96771 45998

- : admin@digitalsolutionstech.com

© Professional Training. 2020. All Rights Reserved

Design and Developed by : xmediasolution.com

Testimonial

Saleem K .Kutty

Senior Engineer - CRISTAL, KSA

Mr. V.B. Hari Krishnan

U H S Engineering - Chennai,India.

Mr. K. Shankar

J S R Sanko India Pvt Ltd - Chennai,India.

Mani Maran

Siva Subramaniyan

Jagadish Babu

Aakash Rajasekaran

R.Selvakumar

Abinaya Manoharran

Tamil Selvan

© Professional Training. 2020. All Rights Reserved

Design and Developed by : xmediasolution.com

- : No.986, Angalamman Koil 3rd street, Kolathur Main Road, Mambakkam Chennai-600127

- : +91-044-27479336

- : +91 96771 45998

- : admin@digitalsolutionstech.com